Introduction

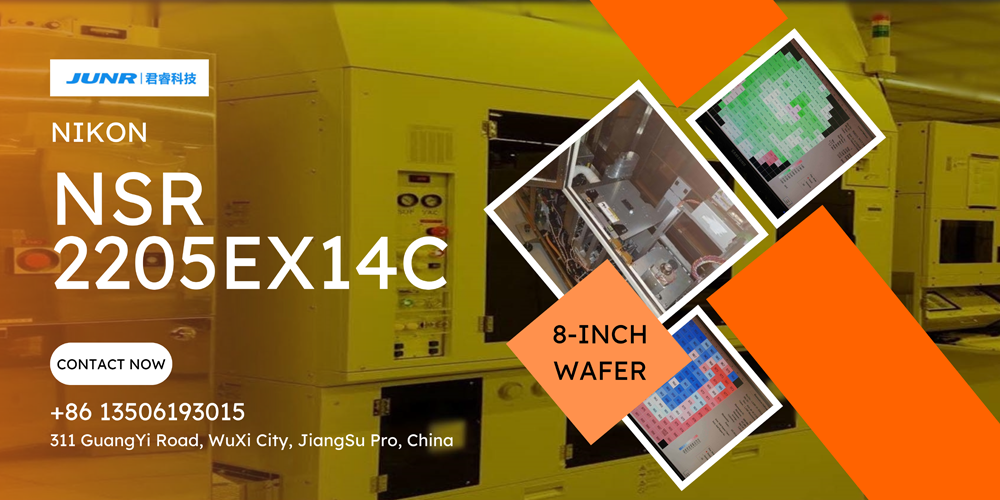

The Nikon NSR-2205EX14C Stepper stands as a hallmark of precision lithography in 8-inch wafer semiconductor production. Known for its reliability and performance stability, it combines advanced optical systems, accurate wafer alignment, and efficient automation — making it one of the most trusted solutions in mid-generation semiconductor manufacturing lines.

Even though this system dates back to the late 1990s, its robust performance and compatibility with modern process control systems continue to make it a popular choice in refurbished equipment markets, especially for foundries and research institutes seeking proven reliability at lower capital cost.

This article provides an in-depth overview of the NSR-2205EX14C — from its technical specifications and key features, to applications, operational advantages, and tips for buyers evaluating used Nikon steppers.

1. Overview of the Nikon NSR-2205EX14C

The NSR-2205EX14C is part of Nikon’s 2200 series — designed specifically for 8-inch (200 mm) wafer lithography. It features a 1/5 reduction ratio projection lens, variable numerical aperture (NA), and a 22 mm exposure field, enabling superior imaging flexibility across diverse device layers.

This stepper is optimized for high throughput and overlay accuracy, leveraging Nikon’s Precision Projection Optics (PPO) and advanced wafer alignment systems to ensure consistent patterning results, even across multiple layers and varying process conditions.

2. Technical Specifications

Below is the detailed specification summary for the Nikon NSR-2205EX14C:

| Parameter | Specification |

|---|---|

| Stepper Type | 8" (200 mm) |

| Reticle Size | 6" |

| Reticle Library Capacity | 10 |

| Exposure Field Size | 22 mm |

| Reduction Ratio | 1/5 |

| Numerical Aperture (NA) | Variable |

| Alignment System | Pre-alignment |

| Wafer Loader | Type 3 |

| Particle Detector | PPD3 |

| Autofocus | Multipoint AF (49 Channels) |

| Inline Configuration | Right (ACT 8) |

| Light Source | EXCIMER ELS 5410 Laser |

| Illumination Power | 1 kW |

| FIA (Focus/Illumination Alignment) | Included |

| LIA (Leveling Illumination Alignment) | Not Included |

| Periphery Exposure | None |

| Base Kit | BASEEX502-0011C |

| Highland Type | Standard |

| Chamber Temperature | 23°C |

| Manufacture Year (Vintage) | 1999 |

This configuration represents a balanced platform for advanced submicron lithography with strong overlay accuracy and thermal stability.

3. Optical Performance and Imaging Quality

At the core of the NSR-2205EX14C is Nikon’s PPO projection lens — designed to achieve submicron imaging with exceptional uniformity. The variable NA provides flexibility for different photoresist and process conditions, allowing users to optimize resolution and depth of focus.

The 22 mm exposure field is ideal for most 8-inch device layouts, while the 1/5 reduction ratio ensures precise pattern scaling with minimal optical distortion.

In combination with the EXCIMER ELS 5410 laser, delivering 1 kW illumination power, this stepper achieves stable energy uniformity across the exposure area — a key factor in maintaining consistent CD (critical dimension) control.

4. Wafer Handling and Alignment Accuracy

Nikon has long been recognized for its alignment precision, and the NSR-2205EX14C continues that legacy.

The Pre-Alignment System and Multipoint AF (49-channel) system guarantee precise wafer positioning and optimal focus across the entire wafer surface. These systems correct for wafer tilt, bow, and local topography variations in real time.

The Type 3 Wafer Loader allows smooth wafer exchange and stable throughput, while the PPD3 particle detector minimizes contamination — ensuring process cleanliness and yield improvement.

5. Automation and Control Systems

Automation is a core advantage of the 2205EX14C model. The inline right configuration (ACT 8) allows efficient integration with coater/developer tracks, reducing handling time and improving overall equipment efficiency.

Key automation highlights include:

-

Wafer pre-alignment automation for fast load/unload

-

Automatic focus correction via multipoint AF

-

Dynamic illumination adjustment for varying photoresist sensitivity

-

Process recipe management through Nikon’s proprietary control interface

Together, these systems deliver reliable repeatability and consistency for both high-volume and R&D operations.

6. Environmental and Stability Features

Stable operation is essential in lithography. The NSR-2205EX14C maintains chamber temperature at 23°C, ensuring consistent optical and mechanical performance.

Its standard highland configuration is optimized for typical cleanroom installations, minimizing vibrations and thermal drift — both critical for overlay and focus accuracy.

These stability features make the NSR-2205EX14C a robust workhorse suitable for fabs running 0.35 µm to 0.25 µm process nodes.

7. System Applications

This stepper supports a wide range of device fabrication processes, including:

-

CMOS and Bipolar devices

-

Analog ICs and power management chips

-

MEMS and sensor components

-

Optoelectronic and LED wafer processing

-

R&D lithography for advanced packaging

Its high precision and proven reliability make it a top choice for pilot lines, academic cleanrooms, and mature-node production facilities seeking stable throughput at low operational cost.

8. Advantages of the NSR-2205EX14C

| Category | Key Benefit |

|---|---|

| Optical System | Variable NA with PPO lens ensures flexible and sharp imaging |

| Alignment Accuracy | Multipoint AF with 49 channels delivers high focus stability |

| Throughput | Automated wafer loader and inline configuration increase productivity |

| Reliability | Proven Nikon mechanical design ensures long-term uptime |

| Cost Efficiency | Lower ownership cost compared to new DUV systems |

| Flexibility | Ideal for R&D and low-to-medium volume manufacturing |

This combination of performance, cost-efficiency, and automation is why the 2205EX14C continues to be highly sought-after in the secondary market.

9. Buying Considerations for Used Nikon NSR-2205EX14C Systems

Purchasing used semiconductor equipment requires careful evaluation. Here are some essential factors to consider:

-

Verify Configuration and Options

Confirm system configuration (e.g., ACT type, AF system, laser model) matches your process requirements. -

Check Laser Source Health

The ELS 5410 excimer laser should be tested for energy stability and pulse uniformity. -

Inspect Optics and Lens Condition

Ensure no contamination, scratches, or coating deterioration. -

Evaluate Alignment Accuracy

Perform test exposures to verify overlay and focus performance. -

Confirm Maintenance History

Well-maintained systems with complete service records tend to perform more reliably. -

Request Reinstallation and Warranty Support

Purchase from a professional refurbisher who offers installation and functional testing.

10. Why the Nikon NSR-2205EX14C Remains a Market Favorite

Despite being a 1999 vintage system, the NSR-2205EX14C remains a benchmark in the 8-inch lithography segment due to:

-

Excellent optical stability

-

Low cost of ownership

-

High reliability under continuous use

-

Ease of integration with coating/developing tracks

-

Availability of spare parts and service expertise

Its longevity in the global semiconductor industry is a testament to Nikon’s engineering excellence.

Conclusion

The Nikon NSR-2205EX14C Stepper embodies Nikon’s long-standing commitment to precision, reliability, and optical excellence. It is an 8-inch lithography solution that continues to serve global fabs with consistency and cost efficiency.

For facilities operating at the 0.35 µm to 0.25 µm nodes, or those seeking affordable, proven stepper platforms, the NSR-2205EX14C is a strategic choice that balances performance with long-term value.

Whether you’re expanding an 8-inch production line or building an R&D lithography lab, this system remains a trusted, industry-tested solution that delivers results.